General

Reed switch technology is the primary sensing element used to generate switch outputs for our differential product. Reed switches are magnetically operated. The reed switch senses the position of a magnet moving in the bore and when the magnet is close enough to the switch, the contacts change state.

Switch Outputs using the reed switch technology are available for our entire product line except the Model 116 and Model 105 / 106 / 109. The Model 116 uses a micro-switch implementation and the 105 /106 / 109 uses electro-optical technology to control output relays. The Model 106 also has an additional option for micro-switches.

Our Model 220 /240 product for Hazardous location has an option for relay outputs where we use reed switches to control the operation of a relay coil.

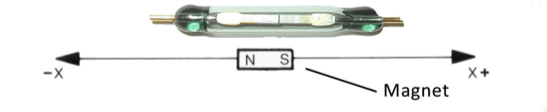

A reed switch consists of four basic parts: 1) glass capsule, 2} gas (Inside the glass capsule), 3) contacts and 4) ferromagnetic leads (reeds). The reeds are hermetically sealed into the glass capsule in a cantilever alignment with a small air gap between them. As the magnet approaches the switch the extreme ends of the reeds become attracted to the magnet, overcoming the stiffness of leads causing them to flex and make contact.

Mid-West Instrument additionally packages the bare reeds in potted enclosures adding further environmental protection.