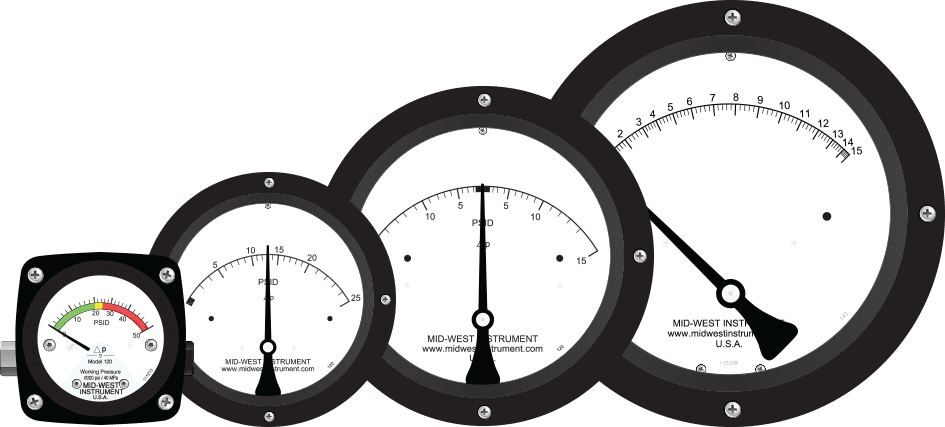

Piston Gauge Description:

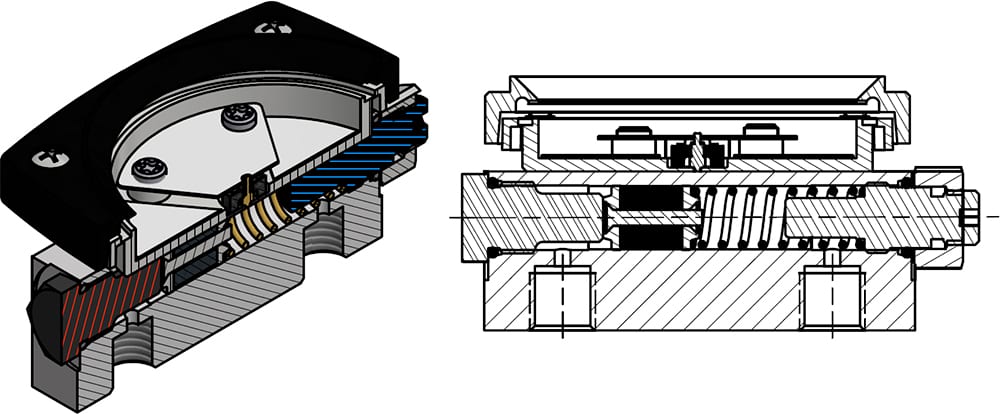

Mid-West® Instrument Piston ΔP Gauges- A precision ground magnetic piston assembly moves against a calibrated range spring in a diamond reamed bore in the gauge body as pressure differential between the high and low ports changes. A rotary magnet on the outside of the body tracks the movement of the magnetic piston and the attached pointer indicates ΔP on a dial.

All piston type gauges allow process fluid to migrate across the piston from high to low side. The precision machining of Mid-West® Instrument piston ΔP gauges limits the migration to a maximum of 32 SCFH air at 100 PSID at ambient conditions. For applications where fluid migration from high side to low side is not tolerable select one of our many Diaphragm type ΔP gauges

Piston-Type Differential Pressure Gauges are available with one or two hermetically sealed reed switches or 4-20mA transmitter depending on model. The switches are adjustable within a defined percentage of the full scale range of the gauge and are available in SPDT and SPST, normally open or normally closed configurations for various load/power ratings. The switches can be set to activate or deactivate on rising or falling pressure. Models 120, 121, 122, 123, & 124 Switches are “CE” marked per the EU Low Voltage and ROHS Directive.

Hazardous location switches Models 120, and 121 are certified CSA and UL to Canadian & US Standards. Model 220 is CSA, UL Listed and CE marked to the ATEX directive and KOSHA certified along with the option for DPDT relays for higher load applications. The CSA & UL listings are for the entire assembly and not just the enclosure. See individual models for complete specifications.

OEM, Private Label, Special Dials

Mid-West Instrument has the capability to design and engineer a Differential Pressure Gauge, Switch or Transmitter to the exact requirements of the customer. Dial size, Process connection Size and location, etc. can also be customized to the customer’s requirements. Mid-West has one of the fastest production times in the Industry. Our standard production time on most gauges is 7-10 business days or less.

Mid-West Instrument has the equipment and printing technology to provide color dials, flow scales and customer logo dials.

Please contact your Sales Coordinator for additional information and terms.