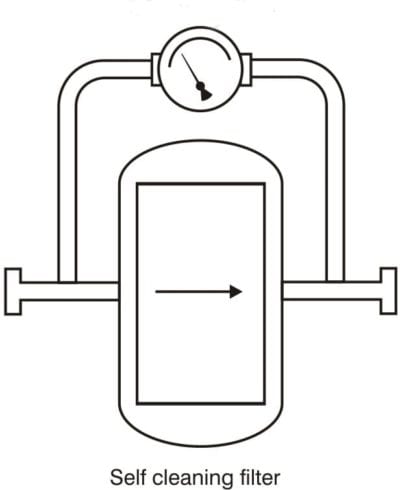

Used to monitor clogging of filter

A Piston or diaphragm type indicating differential pressure gauge with a switch are ideal for monitoring filter conditions. An adjustable switch can initiate a cleaning cycle to self-clean / backwash a filter automatically at a preset differential pressure.