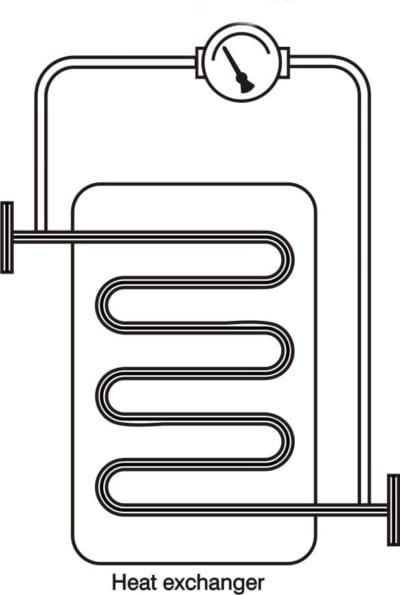

Heat exchangers are vital components in various industrial processes, including transformer oil cooling systems. These systems require efficient cooling to maintain the optimal temperature of the transformer oil, ensuring the equipment operates smoothly and extends its lifespan. To achieve this, a heat exchanger is utilized, which facilitates the transfer of heat from the oil to a cooling medium, typically water.

Importance of Pressure Differential Measurement

In a transformer oil cooling system employing a heat exchanger, maintaining a pressure differential between the oil and the cooling water is crucial. The oil must be kept at a higher pressure than the water to prevent potential water contamination of the oil in the event of a tube leak. If the pressure differential is not adequately monitored and controlled, it could lead to serious issues, jeopardizing the system’s reliability and efficiency.

Diaphragm Type Differential Pressure Instruments

Diaphragm type differential pressure instruments are the preferred choice for measuring pressure differentials in heat exchangers. These instruments are sensitive and accurate, allowing precise monitoring of the pressure drop across the heat exchanger. A diaphragm inside the instrument responds to the pressure difference between the oil and the cooling water, translating it into a readable value.

Differential Pressure Gauge with Alarm Function

To ensure prompt action in case of abnormal pressure differentials, a differential pressure gauge equipped with a switch is employed. The gauge is calibrated to a preset value corresponding to an acceptable pressure differential. If the pressure drop exceeds this threshold, the switch activates an alarm signal.

Signaling Potential Tube Leak and Water Contamination

The primary purpose of the alarm is to alert operators to the possibility of a tube leak in the heat exchanger. A tube leak could lead to an increase in pressure differential, indicating that water might be infiltrating the oil side of the system. Detecting this issue early is essential to prevent further damage and costly repairs. Upon receiving the alarm, operators can investigate and take necessary corrective measures promptly.

The proper monitoring of pressure differentials in heat exchangers is vital for the smooth and reliable operation of transformer oil cooling systems. Diaphragm type differential pressure instruments, combined with an alarm-equipped gauge, enable precise measurements and early detection of potential tube leaks and water contamination issues. By promptly addressing these concerns, operators can ensure the long-term efficiency and performance of the cooling system, enhancing the overall reliability of the transformer equipment.

For your reliable and precise differential pressure gauge needs, contact Mid-West Instrument, a trusted provider of high-quality instrumentation solutions.